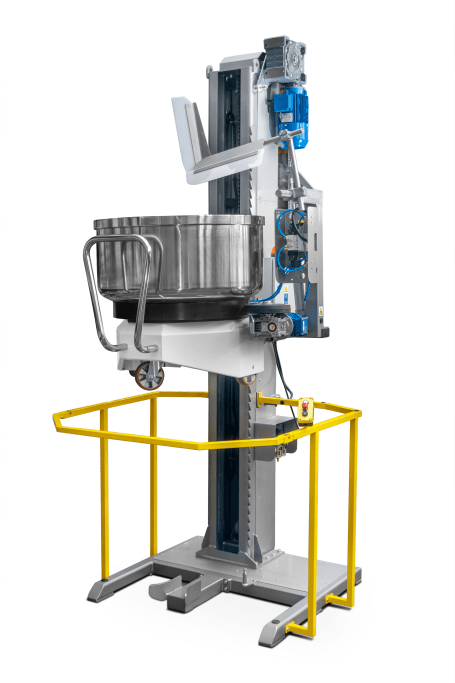

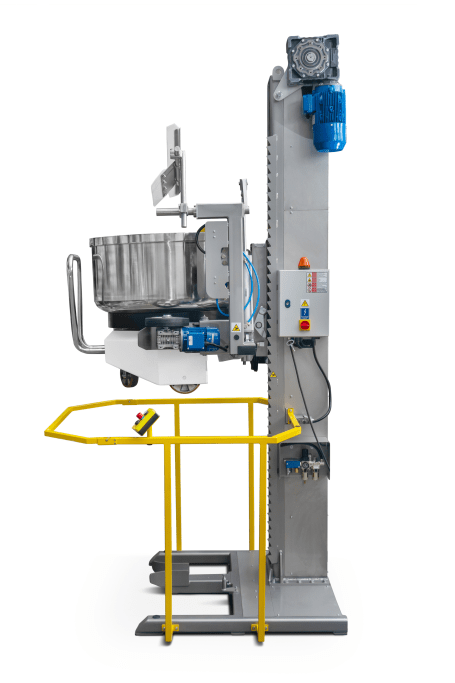

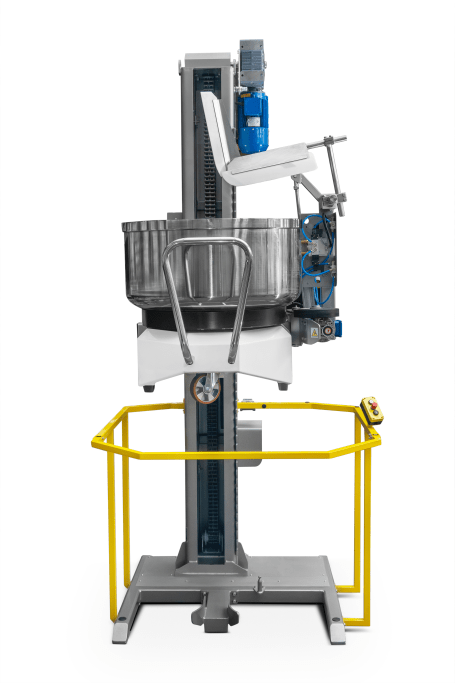

BAKERY TILTER AND BOWL LIFTER

DOUGH LIFTER - BAKERY TILTER

- Custom height available also on request

- Production automation

- Lifting up to 700 kg

Dough bowl tippers and lifters for mobile bakery bowls are an essential addition to any modern bakery. Furthermore, these devices, also known as bakery tilter or bakery lifter, combine ease of operation with durability and precision. Because each bowl lifter is designed to simplify dough transfer processes, while minimizing manual effort and improving safety. Also, whether you need a compact dough lifter for small scale operations or heavy-duty bowl tippers for industrial bakeries. That’s why we provide tailored solutions that meet your exact needs. Additionally, our equipment can be expanded with smart modules, boosting overall workflow efficiency. So contact us to find out how our dough bowl tippers and lifters can transform your bakery’s performance.

Bakery Tilter – Dough Bowl Tippers and Lifters

Firstly, modern bakery production requires high efficiency, consistent reliability, and smooth process automation. Therefore, to meet these expectations, we provide dough bowl tippers and lifters, also called bakery tilter or bakery lifter. Furthermore, they allow for fast, safe, and accurate tipping of dough bowls. Moreover, they integrate easily with dough dividers and spiral mixers. Because this equipment helps streamline production while reducing the chance of injury and operator error.

Applications of Bakery Tilter for Dough Bowl

Mostly, Bowl tippers and bowl lifters automate the process of moving dough to dividers. Also, each machine lifts and tips bowls securely, using wheeled bowl trolleys for easy handling. Additionally, an optional dough lifter module improves workflow and reduces manual effort.

Construction and Operation of the Bakery Dough Tipper

Firstly, our dough bowl tipper adapts to various bowl sizes and can tip left or right. That’s why, in the result, so every bakery tilter includes these key components:

- Base – ensures full stability and safe operation throughout the tipping process.

- Ramp – also allows for quick and smooth loading of the dough bowl.

- Support Column – holds the gear motor and drives the lifting mechanism.

- Lifting Beam – also raises the bowl by pulling a chain inside the support column.

- Rotating Arm – tilts the beam and bowl smoothly during the lifting process.

Furthermore, depending on the production needs, bakery lifters are built from structural or stainless steel. Because stainless steel provides more durability and also protection against corrosion in demanding environments.

Optional Dough Discharge Module

Moreover, our dough bowl tippers and lifters can include a rotating scraper module for improved efficiency. Furthermore, the blade scrapes dough from the bowl as it rises and guides it into the divider hopper. As once finished, the module resets automatically, and the bowl lowers back to its starting point.

Power Supply and Device Customization

Generally, each dough lifter requires a 400V connection. In addition, this provides stable and powerful operation. Furthermore, all our machines comply with CE standards, also ensuring maximum safety and performance. That’s why they are safe to use in every conditions.

Individual Approach to Customers

That’s why we adjust every bakery lifter to the customer’s needs. As a result, the machine fits your production layout. Also, each model can be customized to match space, workflow, and technical requirements.

Advantages of Dough Bowl Tippers and Lifters

- Efficiency and Time Savings – Automation shortens production time and increases daily output.

- Workplace Safety – It also reduces strain and risk from manual tipping and lifting.

- Flexibility – We also offer models with various capacities and tipping directions.

- Excellent Quality – Every bakery tilter is built to last under intense use.

BAKERY DOUGH TIPPER | LIFTING CAPACITY [kg] | LIFTING HEIGHT [cm] | POWER [kW] | LIFTING TIME [s] | DIMENSIONS l. x w. x h. [cm] | WEIGHT [kg] | Universal | 700 | up to 190 | 25 | 1,6 | 100x100x320 | 550 |

|---|

* Because these parameters are for reference only. Furthermore, they may vary depending on individual orders and are influenced by factors. Mostly such as lifting height and the dimensions of the safety barrier.

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl