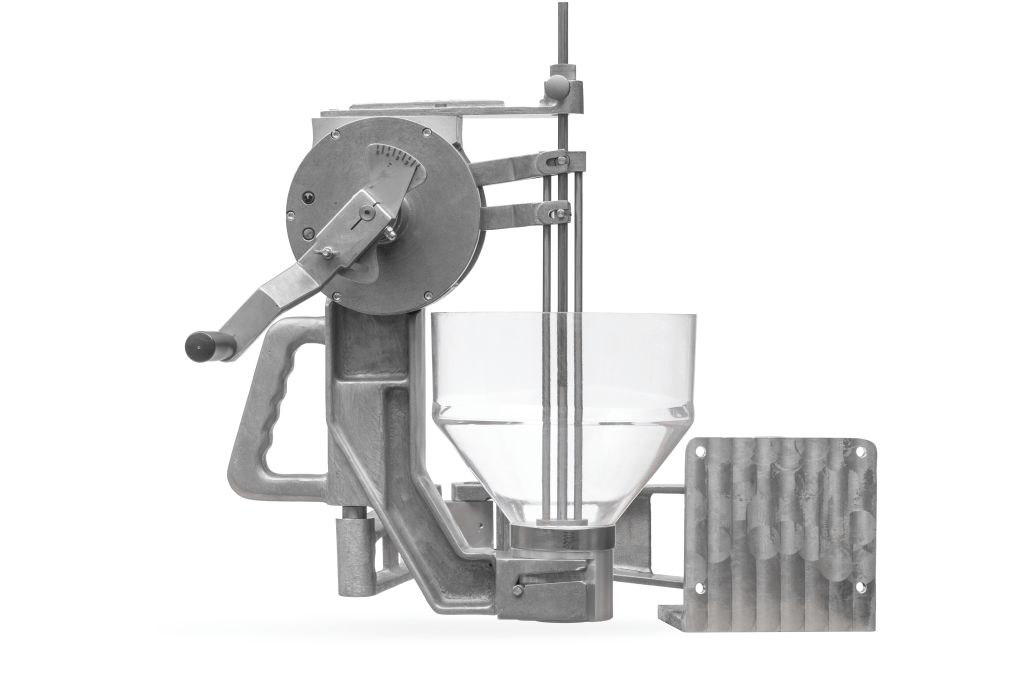

MINI DONUT FILLING MACHINE

MINI DONUT FILLING MACHINE

- Innovative solution

- Easy to use

- Universal application

Our mini donut batter dispenser ensures precise portioning of dough for fried pastries such as donuts and cheese balls, with adjustable weight settings ranging from 10 g to 80 g.

It is available in both manual and electric versions, easy to operate and clean, and its durable construction using aluminum and stainless steel guarantees long-lasting performance. Compliance with CE standards ensures safety and high production quality in confectionery and food service environments.

Innovative Device for Producing Donuts and Cheese Balls

In the production of fried pastries such as donuts, cheese balls, or other baked goods made from light doughs like choux pastry, precise batter dispensing is essential for achieving high-quality results. A modern dosing device is ideal for this purpose, significantly improving the efficiency, precision, and quality of production in confectionery and food service operations.

How Does the Dosing Device for Fried Pastry Production Work?

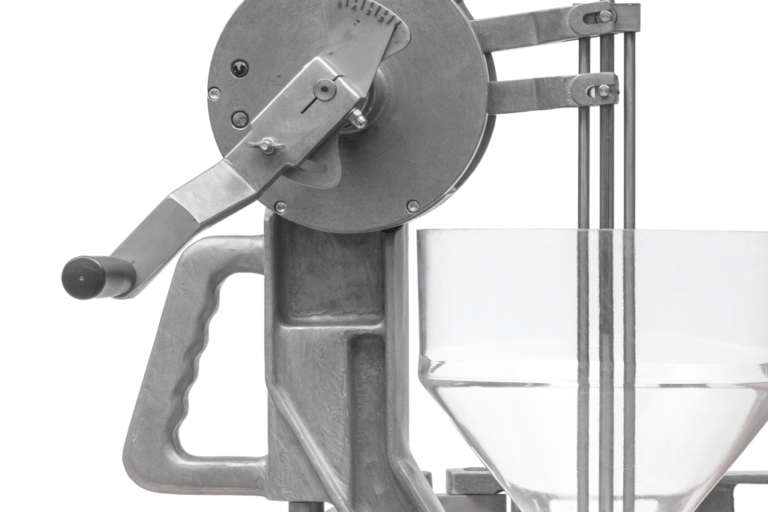

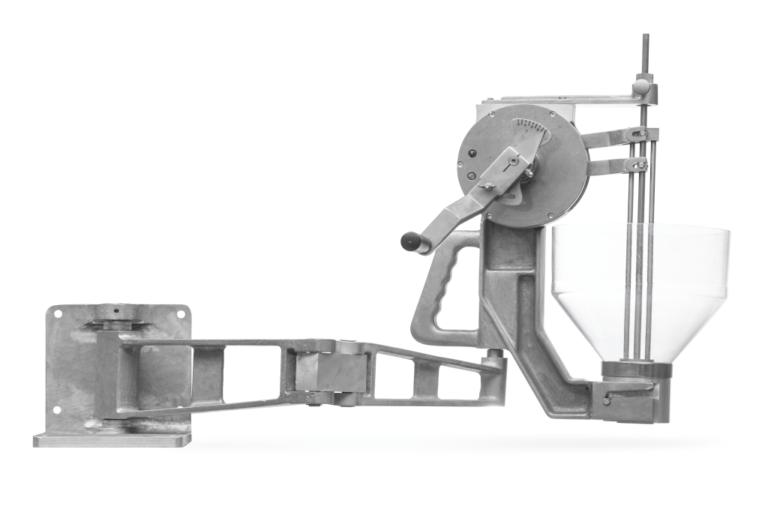

Our dosing device allows for fast and accurate portioning of dough, which is then dispensed directly into hot oil for frying. With a 70 cm rotating arm, one portion of dough is formed with each rotation and dropped directly into the fryer. This system ensures consistent, high-quality baked goods every time.

Flexibility and Performance

The dispenser is available in two versions – manual and electric – allowing adaptation to the specific needs and production conditions of your facility. The electric version offers two operating modes: intermittent and continuous, giving you full control over the dispensing process and the ability to match production speed. Powered by 230V (10 A), it ensures stable performance. The adjustable portion size, ranging from approximately 10 g to 80 g, offers complete flexibility for producing pastries of various sizes.

Industrial Quality and Easy Operation

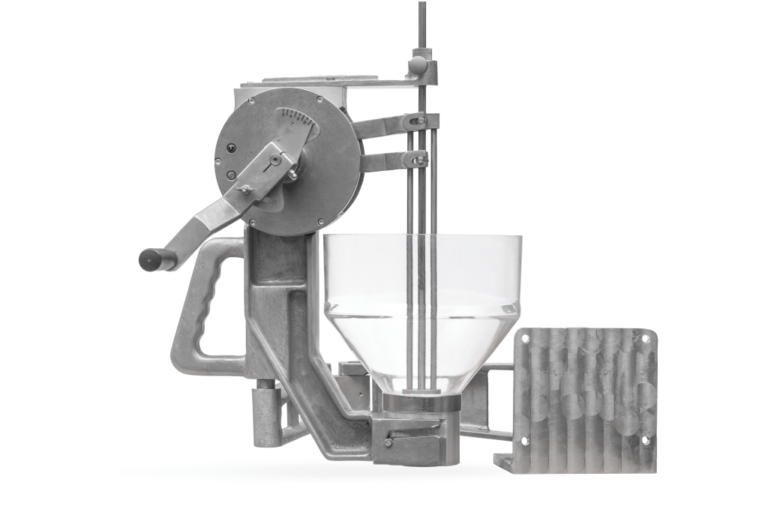

The device is designed for ease of use and cleaning. The housing, body, and tilting arm are made from lightweight yet durable aluminum, while the working mechanisms are made of high-quality, acid-resistant stainless steel—ensuring longevity and resistance to high temperatures. The dosing hopper is made from plastic, making the device easy to keep clean.

Stable Mounting and High Precision

The dispenser is mounted on a double rotating arm, which can be fixed to a wall or table depending on your workspace layout. The mounting must be strong enough to keep the device stable, especially when fully loaded with dough. A key parameter is the distance between the lower cylindrical sleeve and the oil surface—it should be at least 40 mm and no more than 50 mm to ensure safe and precise dough dispensing into hot oil.

CE Standards and Safety

Our dosing device complies with CE standards, meaning it meets European safety and quality regulations. This guarantees reliable and safe operation for years, while maintaining the highest production standards.

Why Choose Our Dosing Device?

- Precise dough dispensing – uniform portions with consistent weight, perfect for donuts, cheese balls, and other fried pastries.

- Two operating modes – manual and electric with adjustable speed control.

- Durability and reliability – made from high-quality materials such as stainless steel and aluminum for long service life.

- Easy to use and clean – intuitive design and simple maintenance.

- CE compliance – safety and quality guaranteed.

Our dosing device is the perfect solution for confectionery operations seeking to increase production efficiency and deliver top-quality baked goods to their customers. With its user-friendly design, reliability, and flexibility in portion control, the production of donuts, cheese balls, and other fried pastries becomes fast, efficient, and flawless.

FILLING MACHINE FOR MINI DONUTS | ARM LENGTH [cm] | DRIVE TYPE | BAKED GOOD WEIGHT [g] | DIMENSIONS l. x w. x h. [cm] | WEIGHT [kg] | DROP | 70 | – manual – motor 230V | 10-80 |

|---|

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl