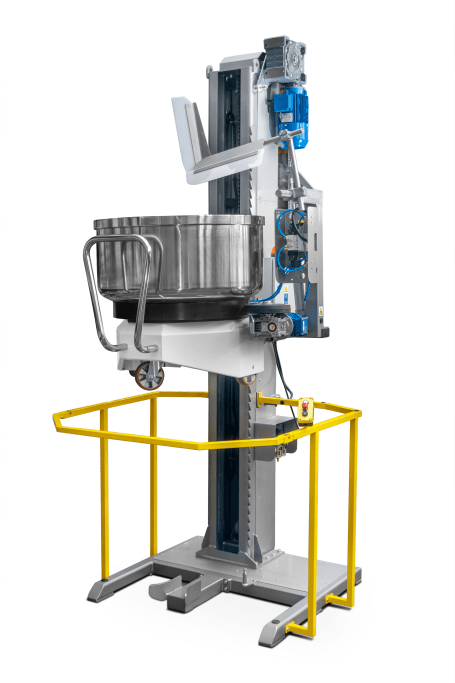

BAKERY TIPPERS FOR BOWLS

BOWL TILTING DEVICE

- Custom height available on request

- Production automation

- Lifting up to 700 kg

Our dough bowl tippers and lifters (for mobile bakery bowls) are an investment that brings value to any bakery business. Thanks to their ease of use, high performance, and the option to expand with additional modules, these devices streamline daily operations and significantly increase production efficiency. Contact us to learn how our dough bowl tippers and lifters can revolutionize your bakery’s processes.

Dough Bowl Tippers and Lifters – Efficient Solutions for Bakeries

Modern bakery production imposes high demands on efficiency, reliability, and process automation. In response to these needs, we offer dough bowl tippers and lifters, which enable fast, safe, and precise lifting and tipping of dough bowls, as well as integration with dough dividers. With these devices, bakery operations become more efficient, while the risk of human error and injuries is minimized. They work perfectly with MASZ Gliwice spiral mixers.

Applications of Dough Bowl Tippers and Lifters

Dough bowl tippers and lifters are an ideal solution for bakeries seeking to automate the process of transferring dough from the bowl to the divider. These machines are designed to lift and tip dough bowls quickly and safely. The dough is transported on wheeled bowl trolleys, ensuring convenient loading and unloading. The devices can be expanded with an additional automated dough discharge module, further increasing efficiency and automation.

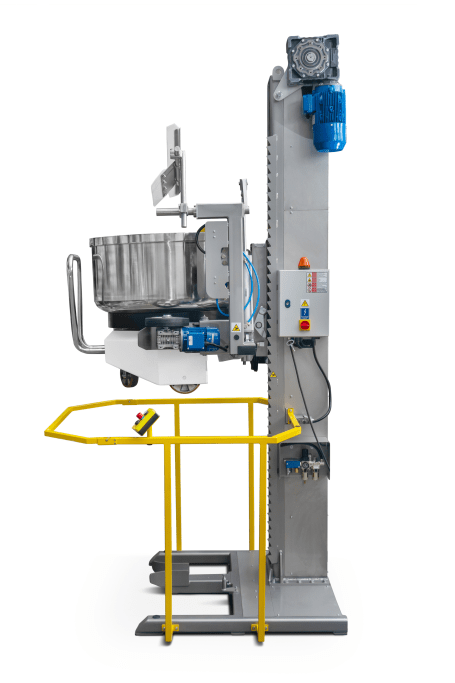

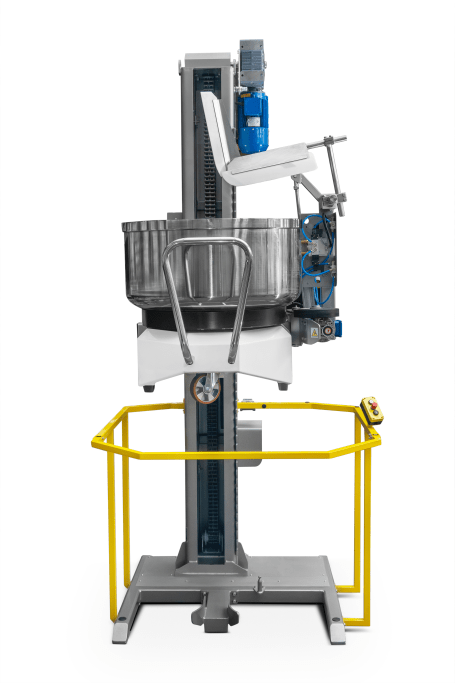

Construction and Operation of the Bakery Dough Tipper

Our dough bowl tipper is designed to fit various bowl capacities and can tip to the right or left side—according to customer requirements. Each bakery tipper consists of several key components:

- Base – provides a stable foundation for the entire structure, ensuring safe and stable machine operation.

- Ramp – allows easy loading of the dough bowl onto the machine.

- Support Column – with a gear motor mounted on top that drives the chain wheel.

- Lifting Beam – the bowl is raised by the beam, which is pulled by a chain housed inside the support column.

- Rotating Arm – responsible for tilting the beam and tipping the bowl during the lifting process.

Depending on the requirements, dough bowl tippers and lifters can be made of structural steel or, upon request, stainless steel, offering greater corrosion resistance, especially under intensive use conditions.

Optional Dough Discharge Module

One of the key advantages of our dough bowl tippers and lifters is the option to add a dough discharge module. It consists of a housing attached to the horizontal beam of the bakery tipper, with a rotating set of blades that scrape dough from the bowl walls. Once the bowl reaches the appropriate height, the dough begins to flow into the divider hopper. At that moment, the dough drive system and scrapers are automatically activated. After the process is completed, the module returns to its starting position, and the bowl with the trolley is lowered back to the base level.

Power Supply and Device Customization

Our dough bowl tippers and lifters require a 400V power supply, which ensures high power and stable operation in high-performance bakeries. Additionally, all our tippers are manufactured in compliance with the current CE standards, guaranteeing safety and reliability.

Individual Approach to Customers

Each device is customized to the client’s specific needs, which allows for modification of certain structural elements based on the unique requirements of the bakery. The standard technical specifications of the machine can be adjusted to perfectly match the production and spatial conditions of your bakery.

Advantages of Dough Bowl Tippers and Lifters

- Efficiency and Time Savings – automation of the tipping process significantly shortens work time and improves production output.

- Workplace Safety – thanks to automated systems, the risk of injuries associated with manual bowl tipping is reduced.

- Flexibility – available in versions adapted to various bowl capacities and tipping directions.

- Excellent Quality – bakery tippers are made of high-quality structural or stainless steel, ensuring durability and resistance to heavy use.

BAKERY DOUGH TIPPER | LIFTING CAPACITY [kg] | LIFTING HEIGHT [cm] | POWER [kW] | LIFTING TIME [s] | DIMENSIONS l. x w. x h. [cm] | WEIGHT [kg] | Universal | 700 | up to 190 | 25 | 1,6 | 100x100x320 | 550 |

|---|

*Parameters are for reference only. They may vary depending on individual orders and are influenced by factors such as lifting height and the dimensions of the safety barrier.

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl