Dough Moulder – An Indispensable Machine in a Modern Bakery

In a bakery where time, quality, and precise production processes matter, every machine plays a key role in achieving high-quality baked goods. Because one such device that speeds up work and ensures excellent results is the dough moulder. Therefore, this machine is gaining increasing recognition in bakeries around the world. Furthermore, it enables effective shaping of dough for a variety of baked products, which translates to higher production efficiency and quality. So, in this article, we’ll have a closer look at what a dough moulder is and why it’s worth having one in your bakery.

1. What is a dough moulder?

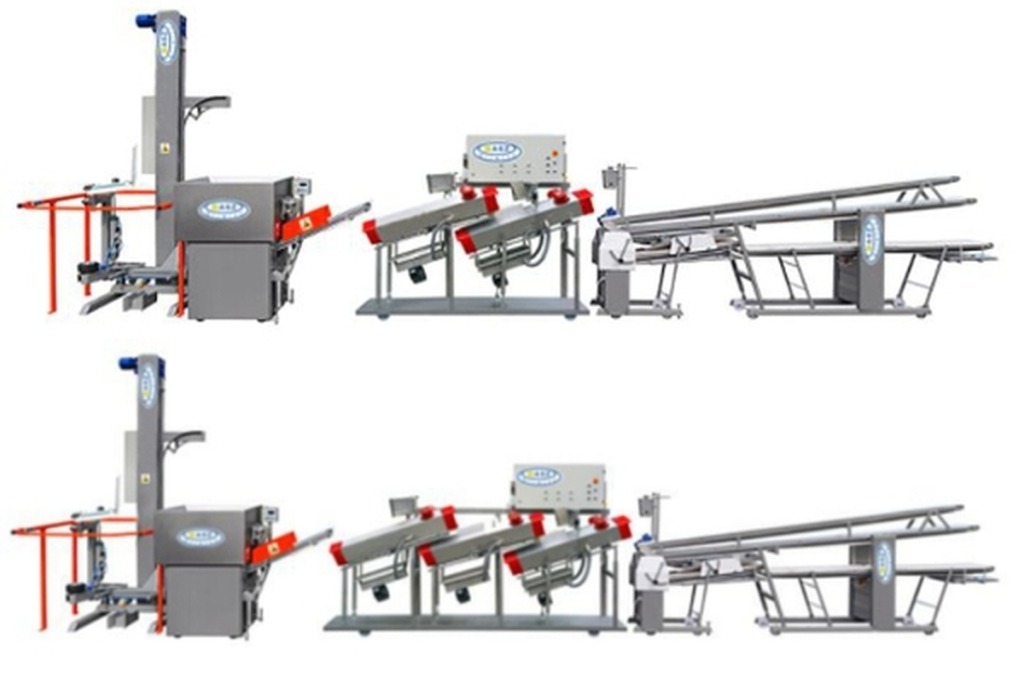

A dough moulder is a device used to shape and pre-stretch dough before further processing, such as forming into loaves, rolls, or other baked goods. Using a dough forming machine helps achieve the right dough structure, ensuring proper aeration and moisture distribution. This device is essential especially for making bread, rolls, or yeast-based doughs that require precise stretching and shaping. Moreover, a bakery dough moulder typically features rollers that gradually stretch the dough while maintaining its consistency and moisture. As a result, the baked goods have the right texture and flavour after baking. The device automates the entire process, saving time and manual labour while increasing production efficiency.

2. How does a dough forming machine work?

The operation of a dough moulding machine is based on simple yet effective principles. Once the dough is inserted into the machine, it is passed through a set of rollers that gradually stretch it to the desired length. Therefore, depending on the machine settings, the dough can be stretched to various extents, allowing the device to be tailored to different types of bread.

- Dough insertion: The pre-prepared dough is fed into the moulder. This could be yeast dough, bread dough, or dough for rolls, depending on production needs.

- Stretching and elongation: Once inside the machine, special rollers begin stretching and smoothing the dough. It passes through several sections of the machine, where it is gradually stretched while retaining its structure, moisture, and internal air content.

- Custom adjustment: The dough forming machine allows you to adjust the stretching process, resulting in dough with the desired consistency and structure. With this adjustability, the baker can control the size and length of the dough pieces moving on to the next production stages.

- Ready dough: After passing through the machine, the dough is ready for further processing, such as forming, dividing, or direct baking. The final dough portions have a uniform texture and are ready for the oven.

3. Advantages of having a dough moulder in your bakery

1. Increased production efficiency

Thanks to the dough moulder, the stretching process becomes quick and precise, significantly speeding up production. In bakeries producing large quantities of bread, automating this production step saves valuable time and reduces the need for manual labour. A dough moulder can greatly increase bread production efficiency, allowing the bakery to produce more in less time.

2. Uniform dough structure

A dough moulder ensures even stretching of the dough, resulting in a consistent structure of the baked goods. This uniformity ensures that every product has the same consistency, which is crucial during baking. Products with a uniform structure bake evenly, improving their quality, taste, and appearance.

3. Reduced manual labor

Manually stretching dough is time-consuming and requires precision, increasing the risk of errors. The dough moulder automates this process, eliminating the need for manual shaping. This allows bakers to focus on other production stages, making bakery operations more efficient.

4. Precise process control

The dough moulder offers precise control over stretching parameters, giving bakers full control over the production process. The machine can be adjusted to the type of dough and the desired specifications, enabling the production of various types of bread. This precise control ensures excellent quality in baked goods.

5. Reduced raw material waste

A dough moulder reduces the risk of over-handling the dough, which can lead to waste when using traditional methods. With even stretching, the dough is fully utilized, leading to lower material losses and greater economic efficiency.

4. When is it worth investing?

Investing in a dough moulder is especially worthwhile for bakeries producing large quantities of bread, rolls, yeast doughs, or other products that require precise shaping. Therefore, this device allows for large-scale production while maintaining high quality and product consistency. Furthermore, if your bakery struggles to meet high demand, a moulder is a great solution to increase production efficiency. Dough machine moulder is a key device in modern bakeries, significantly improving production efficiency, product quality, and reducing the risk of human error. Because it enables quick, efficient, and precise dough stretching, resulting in uniform product structure and enhanced appearance. So, if you want to boost production, save time, and improve the quality of your baked goods, investing in a dough moulding and rounding is a step toward modernity and bakery success.