The Most Common Mistakes in Operating Bakery Machines

Modern bakery machines are invaluable in the daily work of bakeries – they improve efficiency, streamline processes, and ensure product consistency. However, even the best equipment won’t deliver results if misused. Improper operating bakery machines leads to downtime, raw material waste, and even equipment damage. Below are the most common mistakes made by bakery machine operators – and practical ways to avoid them.

Lack of Training or Inadequate Operator Instruction

One of the most serious mistakes is insufficient knowledge of machine operation. Employees often learn “on the job” from colleagues, without reading technical documentation or manufacturer instructions. Furthermore, this is especially problematic with complex systems like an integrated bread production line, where each stage must be precisely synchronized.

How to avoid it?

Always provide comprehensive introductory training for new staff, ideally with input from service technicians or the manufacturer. Also, conduct regular refresher sessions – even experienced operators may forget critical procedures related to operating machines in a bakery.

Skipping Regular Cleaning and Maintenance

Residues, dough buildup, and flour dust can lead to machine failure. Also, lubrication recommendations and component wear inspections are often ignored. So, this is especially important for continuous systems like a dough production line, where a single module failure halts the entire process.

How to avoid it?

Implement daily cleaning routines and weekly/monthly maintenance checklists. Use service logs and require staff to confirm each completed task. Furthermore, always follow manufacturer service guidelines when operating bakery machines.

Overloading Machines Beyond Capacity

Common mistakes include overfilling spiral mixers or dividers beyond their rated capacity. Moreover, this shortens motor lifespan and risks component damage, especially in continuous-use settings like a dough production line.

How to avoid it?

Always check the maximum capacity and never exceed it. If production increases, consider purchasing a second unit or a larger model instead of risking machine failure from improper operation of bakery machines.

Operating Bakery Machines – Incorrect Parameter Settings

Mixing too fast, improper pressure in a rounder, or incorrect oven temperature – such errors directly affect product quality. Therefore, in automated systems like a bread production line, one misconfigured unit can disrupt the entire workflow.

How to avoid it?

Record proven settings for each product type. Use programmable settings whenever possible to avoid human error. Limit parameter access to trained staff who fully understand how to operate bakery machines correctly.

Operating Bakery Machines – Ignoring Early Warning

Unusual noises, delayed starts, or inconsistent performance often signal emerging issues. Unfortunately, they are often ignored until a full breakdown occurs. Because in a bread production line, even minor faults can halt production and cause significant losses.

How to avoid it?

Implement a policy for immediate reporting of unusual machine behaviour. Furthermore, conduct routine technical inspections – even if the machine “seems fine.” Early detection is a critical part of operating machines in bakery effectively.

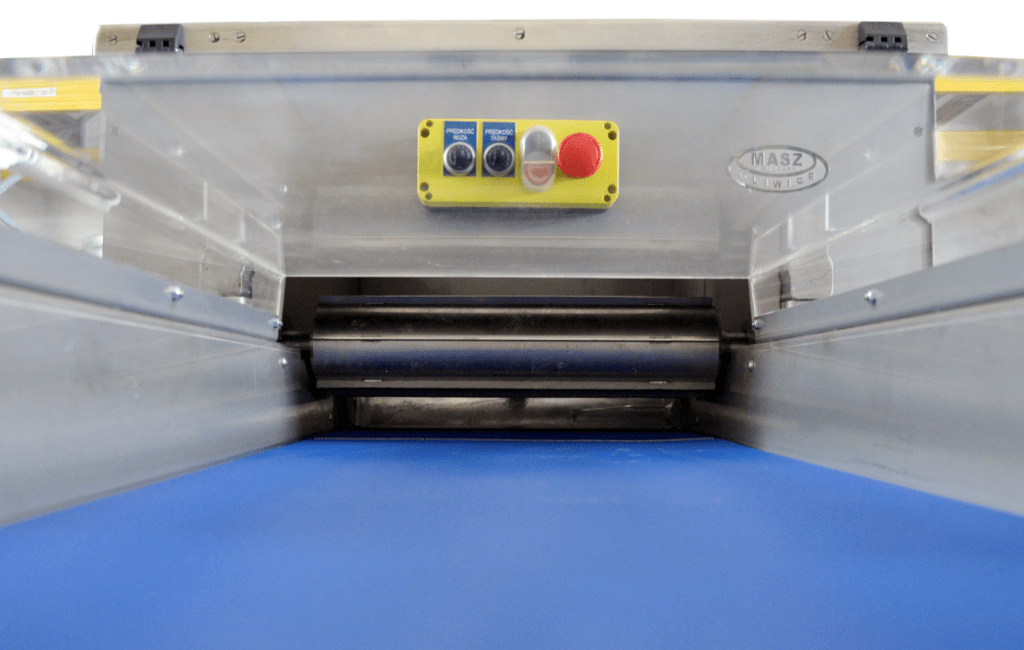

Improper Use of Safety Features

Emergency stops, door sensors, or safety interlocks are sometimes bypassed or disabled. This not only violates health and safety regulations but poses a real threat to workers – especially on large machines within a dough production line.

How to avoid it?

Train staff on safety and accountability. Regularly inspect safety systems and never operate machines without covers or with disabled sensors. Safety should be central when operating bakery machines of any kind.

Lack of Operational and Service Documentation

Many facilities keep no records of part wear, inspections, or technical issues. This makes it harder to diagnose faults and schedule preventative maintenance.

How to avoid it?

Create machine operation logs and introduce an electronic system for reporting faults. Furthermore, for large facilities using an automated bread or dough production line, this is essential for planning preventive service and maintaining smooth bakery machine operation.

Bakery automation offers many benefits, but only when paired with a strong technical culture and organized operations. Whether you use individual machines or full bread and dough production lines, skilled and trained operating of bakery machines is essential. So, by eliminating common mistakes, you can reduce failures and losses while increasing efficiency and product quality.