MIXER FOR STUFFING - SPIRAL MIXER

Stuffing Mixers for Food Industry

Efficient, Durable, and Reliable Stuffing Mixers

Our filling mixers combine strength, efficiency, and modern control to support reliable food production. Because every facility has different needs, we offer machines in several sizes and capacities. That’s why, each mixer for stuffing handles daily production with speed, precision, and high consistency. Moreover, thanks to compact design, our machines fit both small workshops and industrial-scale processing lines. In addition, the electric stuffing mixer includes reinforced components, which support continuous operation and minimize wear. Moreover, smaller bowl capacity still delivers strong performance and better energy efficiency. As a result, these machines reduce power use while maintaining top-level productivity every day.

Mixer for Stuffing – Modern Technology

Basically, all stuffing mixers by MASZ Gliwice use acid-resistant or stainless steel for better durability. Because of their high resistance, they work well in harsh or demanding environments. In addition, the mixers meet CE standards, which guarantees safety and compliance with EU regulations. Also, user-friendly control panels ensure quick adjustments and improve workflow for every operator. That’s why quiet operation also creates a more comfortable and productive workspace in food facilities.

Mixer for Stuffing in food industry

Even ingredient mixing improves filling quality, texture, and final product consistency. Furthermore, we also offer spiral mixers and spiral filling mixers for large-scale mixing tasks. Moreover, these machines ensure fast, uniform mixing and perfect for intensive, high-volume food production needs.

Mixers for Various Industries

The Power of the Mixer Matters

The stuffing mixers we offer play a key role in the gourmet food industry. They handle meat fillings, dumpling fillings, and dense mixtures with excellent consistency. Because thanks to powerful motors, each mixer for stuffing ensures efficient and uniform blending every time. In addition, our clients appreciate their performance in preparing coleslaw, salads, and vegetable mixes. Because of reinforced design, these machines also work well for dry and wet pet food. Moreover, each model can mix granules, pastes, or similar products with different textures. Every spiral mixer in our range offers reliability, strength, and easy maintenance. As a result, our machines improve workflow and help reduce manual labour in food production.

Mixer for Stuffing - how to choose?

- Efficiency and Energy Savings – Our machines boost productivity while lowering energy consumption.

- High Performance – HRT models deliver strong output in compact form, ideal for ready-meal sectors.

- Durability and Reliability – Reinforced design and premium materials ensure long-lasting, stable operation.

- User-Friendly Operation – A clear touch panel and simple layout make daily work smooth and efficient.

- Adapted for Ready-to-Eat Production – We offer various capacities with customization to match specific production needs.

- Comprehensive Service – We include a 2-year warranty and full after-sales support for trouble-free operation.

So, if you need dependable equipment for mixing and preparing fillings, explore MASZ Gliwice’s full range. In addition, our many years of experience help us deliver machines that support fast, consistent, and high-quality filling production.

Furthermore, for professionals seeking proven solutions – choose mixers from MASZ Gliwice

STAINLESS STEEL SPIRAL DOUGH MIXER

Industrial Spiral Mixer – Stainless Steel

A high-quality spiral mixer made from acid-resistant stainless steel is a key machine in any modern bakery or food processing plant. That’s why its durable construction and hygienic surfaces make it ideal for environments that demand regular washing and constant use in high humidity. Therefore, one of the most popular options in our range is a bakery mixer with a removable bowl, created specifically for continuous, high-load operation. The device also combines quiet performance with an intuitive control panel and a two-speed motor, offering excellent mixing results along with operator comfort. Thanks to its versatile design, this model functions perfectly as a mixer for the food industry, as well as for catering services, deli production, and ready-meal processing. It also supports efficient workflows while maintaining high-quality output across different food sectors.

"Why Mixer FOR STUFFING FROM MASZ GLIWICE?

Efficiency and Reliability – Our filling mixers deliver excellent performance, helping speed up dough and filling preparation. In addition, the spiral mixing mechanism ensures uniform blending and precise ingredient distribution in every batch.

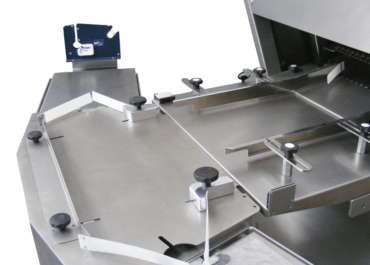

Simple Operation and Easy Cleaning – Our HRT spiral mixers feature a stainless steel bowl and a hinged safety cover with a microswitch for secure operation. Furthermore, their ergonomic design simplifies everyday use and allows quick, hassle-free cleaning with minimal downtime.

Durability and Long-Term Strength – Moreover, created from premium materials, these mixers are ready for heavy-duty, long-term use. Also, the solid structure and optional stainless steel finish offer excellent resistance to wear, mechanical damage, and corrosion, which extends the machine’s lifespan.

Additional Mixer Options

So, if our spiral mixers exceed your capacity requirements, we encourage you to view our selection of confectionery mixers and bakery mixers. Because these compact models are designed with smaller bowls, making them ideal for low-volume or speciality production.

NEWS ON THE BLOG

Bakery Machines – Innovative Bakery Equipment

Industrial Bread Slicers – When Is It Worth Investing?

Acid Resistant Steel Mixer – Why It Pays to Invest in a Durable Dough Mixer

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl