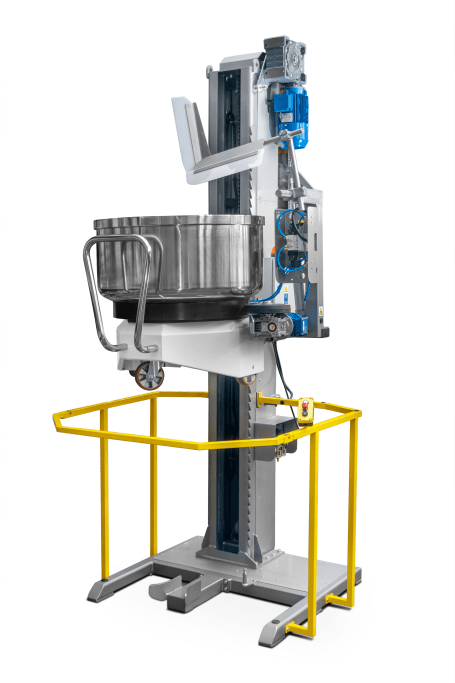

DOUGH MIXER - SPIRAL MIXER HRT

DOUGH MIXER FOR HEAVY DOUGH

- For masses with low water content

- Intuitive touch screen panel

- Versatile application

Basically, our dough mixers with both fixed and removable bowls offer high performance and reliability, also making them ideal for bakeries, pastry shops, and all other food industry sectors. Therefore, they are designed for mixing dough with a water content of less than 40%, with a minimum mixing quantity of approximately 10% of the bowl’s maximum capacity. Furthermore, models with a hydraulically lifted head and a belt-driven system ensure quiet operation and user comfort. Also these spiral mixers allow for precise adjustment of operating parameters, making them perfect for producing both small and large batches of dough.

Dough Mixer with Removable Bowl – Efficiency and Reliability Across Industries

Generally, we offer spiral dough mixers with removable bowls (HRT) for various industries. In addition, these dough mixer spiral models efficiently mix dough with less than 40% water content. Because they support both small and large batches, you can load as little as 10% capacity. Therefore, they’re ideal for bakeries, pastry shops, and sectors like pet food and ready-meal production.

Durable Construction and High Performance

At the start, each dough mixer has a painted steel body, while stainless steel options are also available. Furthermore, the spiral, bowl, scraper, and cover are all made from acid-resistant stainless steel for durability. In addition, you can request a full plastic cover to improve protection against outside contamination.

Bakery mixer – Quiet Operation and Dependability

Basically, a modern belt system makes every spiral mixer run smoothly and very quietly. Therefore, models with removable bowls include hydraulic lifting and automatic locking for improved workflow and safety. Because safety matters, the locking system engages automatically to support the operator.

Easy Operation and Precise Control

At the beginning, you can basically control the mixer easily with the simple interface and two-speed settings. It also monitors dough temperature, so you avoid overheating during mixing. Furthermore, if needed, the machine works in manual mode during any electronic system failure. In addition, this dough mixer spiral adjusts easily based on your recipe and ingredients.

Mixers for Bakery- Wide Range of Applications Across Industries

Additionally, Spiral mixers are great for more than dough because they mix fillings, vegetables, pastes, and pet food. Also, a strong dough mixer also handles low-hydration bread or pizza dough without any issue. Because of their power and durability, these mixers serve many food-processing needs.

Manufactured in Compliance with CE Standards

Because every dough mixer we produce meets current CE safety and design standards. In addition, you can choose stainless steel finishes or touchscreen panels to match your production scale. So, that’s why you get a mixer that works efficiently while meeting strict quality expectations.

MIXERS FOR STIFF DOUGH | CAPACITY ACCORDING TO DOUGH WEIGHT [kg/l] | BOWL DIAMETER [Ø] | POWER [kW] | DIMENSIONS l. x w. x h. [cm] | WEIGHT [kg] | HT 100 | 100 / 180 | 75 | 9 | 155x89x153 | 770 |

|---|---|---|---|---|---|

HT 150 | 100 / 260 | 86 | 9 | 155x89x153 | 805 |

HRT 100 | 100 / 180 | 75 | 10,5 | 164x93x146 | 1102 |

HRT 150 | 150 / 260 | 86 | 14 | 170x103x146 | 1253 |

HRT 200 | 200 / 320 | 94 | 18,7 | 194x113x164 | 1557 |

Efficient Integration and Bowl Handling

Basically, dough mixers work especially well with modern dough lifters and bowl tippers. Furthermore, these systems lift and tilt bowls smoothly to any required height and direction. As a result, the dough can be transferred precisely to the next processing step. This also includes dividers, fermentation containers, or feed hoppers. Therefore, there is no need to move or rearrange production equipment. Therefore, the tipping system is usually hydraulic or electric. Moreover, it allows clean, controlled, and complete emptying of bowls. Additionally, in some setups, sensors monitor tipping speed and position in real time. In addition, stainless steel construction ensures hygiene and easy cleaning. Also, Some designs allow tipping to both sides or forward, depending on the layout.

Better Ergonomics and Safer Production Flow

Firstly, by using a bakery lifter, employees no longer lift heavy dough manually. That’s why, as a result, workplace injuries are reduced significantly. Furthermore, the transfer process becomes faster, safer, and more consistent. Moreover, in many bakeries, this setup increases daily production output with less strain on staff. Because bowl tippers are tailored to fit different bowl sizes and heights. That’s why, they can also match existing production lines with minimal adjustments. Furthermore, in most cases, setup time is short, and also maintenance needs are low. Therefore, combining a dough mixer with a dough lifter and bowl tippers is the first step toward automation. Basically, it brings better efficiency, cleaner workflows, and modern standards to your dough production line.

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl