BAKERY MIXER - MIXER MACHINE FOR BAKERY

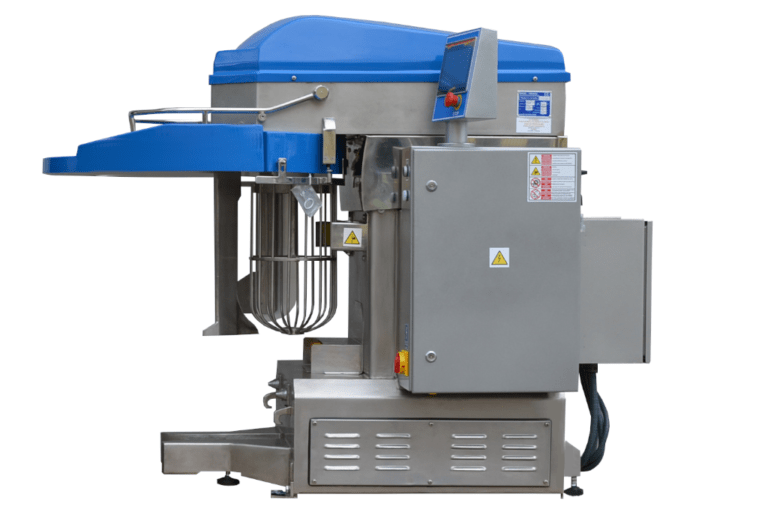

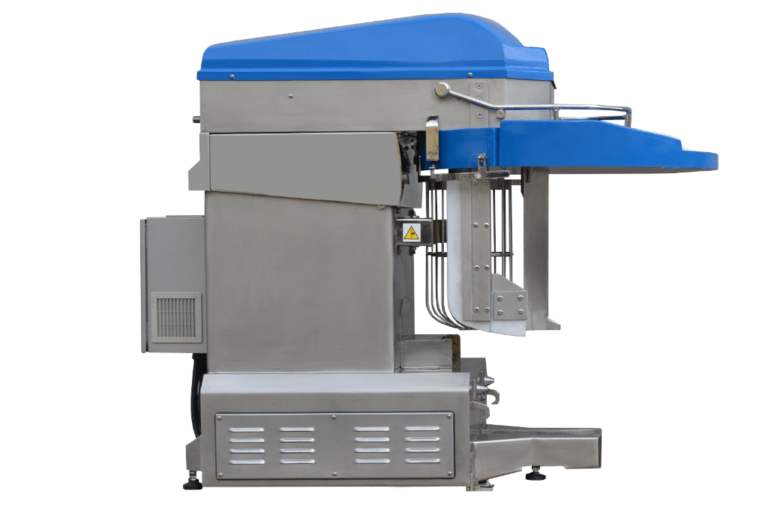

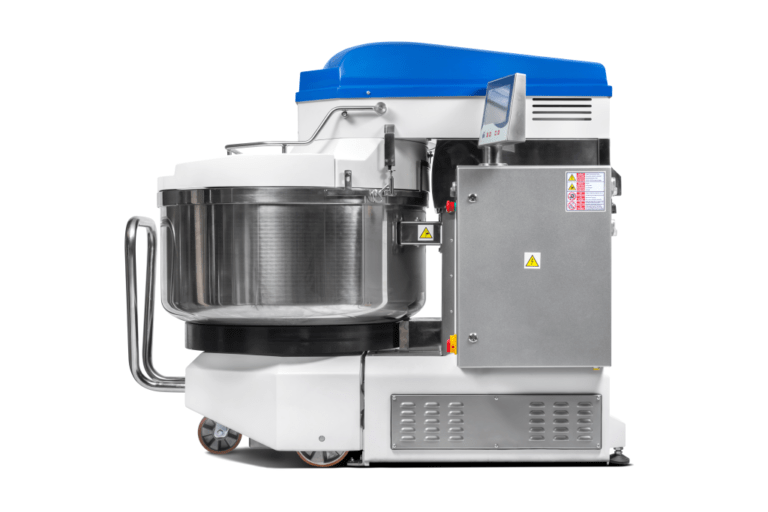

CONFECTIONERY MIXER SMRU

- Hight capacity

- Proven and efficient design

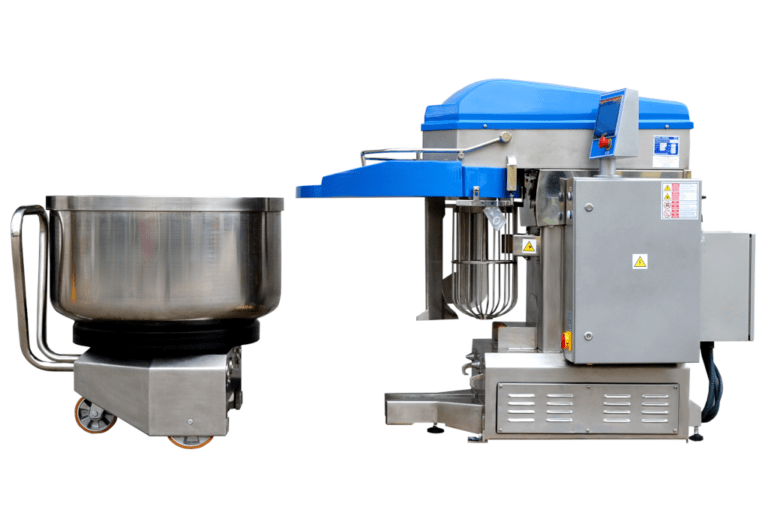

- Removable bowl

Generally, high-capacity mixer SMRU works as a reliable and efficient bakery mixer, ideal for modern pastry and confectionery needs. Furthermore, it combines quiet operation, advanced technology, and strong construction, supporting both consistent quality and faster production. Additionally, the mixer machine for bakery includes various mixing tools, which allow easy adaptation to different recipes and batch sizes. Whether you’re preparing creams or thicker doughs, this bakery mixer ensures smooth and even results. What’s more, the user-friendly interface and low-noise performance create a comfortable work environment. As a result, the mixer machine for bakery becomes a smart choice for bakeries seeking precision, flexibility, and long-term reliability.

Bakery Mixer with Removable Bowls – A Smart Choice for Modern Production

Generally, a high-performance mixer with removable bowls offers excellent support for professionals in the confectionery and baking industries. Furthermore, as demands grow, many facilities choose this mixer machine for bakery because it combines reliability with high capacity and ergonomic design. What’s more, it significantly improves efficiency while maintaining product quality. Moreover, thanks to its versatility, the bakery mixer machine easily adapts to various recipes and scales of production.

Designed for Precision of Bakery Mixer

Furthermore, this mixer machine for bakery serves both artisanal and industrial purposes. Additionally, with bowl capacities ranging from 130 to 350 liters, users can work comfortably on small batches or high-volume processing. Moreover, the machine supports continuous production with minimal downtime, which proves crucial in demanding work environments.

Durability, Hygiene, and Smart Construction

Basically, constructed with powder-coated steel or optional stainless steel, this dough mixing machine withstands daily use while remaining easy to clean. Moreover, all components in contact with food are made of acid-resistant stainless steel, which enhances hygiene and ensures compliance with food safety standards. Also, an optional full plastic cover improves user protection and workflow comfort.

Low Noise and Hydraulic Efficiency

The machine operates quietly, thanks to its belt-driven mechanism. Furthermore, this feature creates a more pleasant working atmosphere, especially in compact or open kitchen environments. In addition, the hydraulic lifting system makes handling bowls much easier and safer. Because the head lifts automatically, and the bowl locks securely in place, also reducing manual labour and saving time.

Touchscreen Control and Workflow Automation

Equipped with a user-friendly touchscreen, the bakery mixer machine allows for precise control of mixing speed, time, and tool function. Moreover, users can store mixing programs, monitor ingredient temperature, and also optimize production consistency. Because this system makes daily tasks more manageable and reduces the chance of human error, which is critical in large-scale operations.

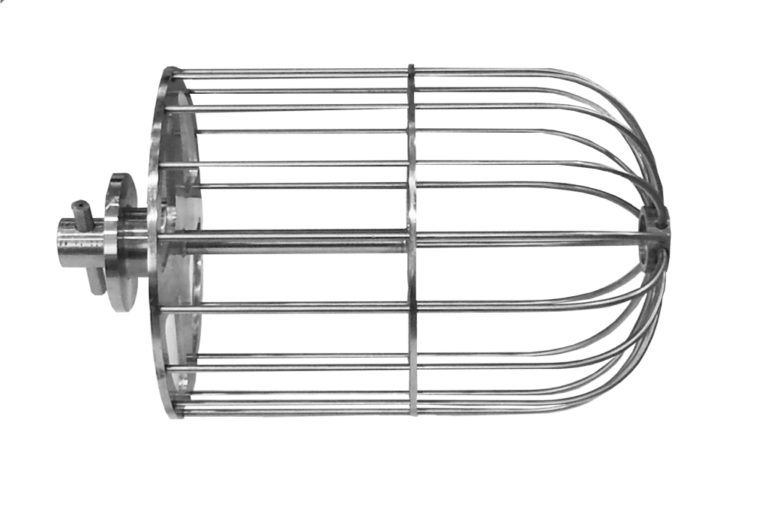

Flexible Features and Tool for Bakery Mixer

Moreover, manufacturers often include useful add-ons, such as a water dosing system and quick-release tool changers. What’s more, these enhancements allow for greater accuracy and speed during production. Moreover, the mixer supports a wide range of attachments, including paddle, whisk, and cross-blade tools. Also allowing bakers to process everything from creams to doughs with ease.

Why Mixers for Bakery Are a Smart Investment

Because choosing the right mixers for bakery means more than just improving performance. It also means building a dependable production system. Furthermore, with strong construction, ergonomic handling, and full automation support, this mixer also proves to be a long-term solution that grows with your business. Whether for a small shop or an industrial bakery, investing in a powerful mixer machine for bakery brings both quality and peace of mind.

CONFECTIONERY MIXER | CAPACITY BY DOUGH WEIGHT [l] | BOWL DIAMETER [Ø] | POWER [kW] | BOWL MOTOR POWER [kW] | DIMENSIONS l. x w. x h. [cm] | WEIGHT [kg] | SMRU 130 | 130 | 70 | 3,7 | 0,5 | 147x85x128 | 755 |

|---|---|---|---|---|---|---|

SMRU 180 | 180 | 75 | 5 | 1,1 | 149x87x128 | 795 |

SMRU 260 | 260 | 86 | 6 | 1,1 | 158x93x138 | 848 |

SMRU 350 | 350 | 100 | 11 | 1,5 | 175x106x156 | 1170 |

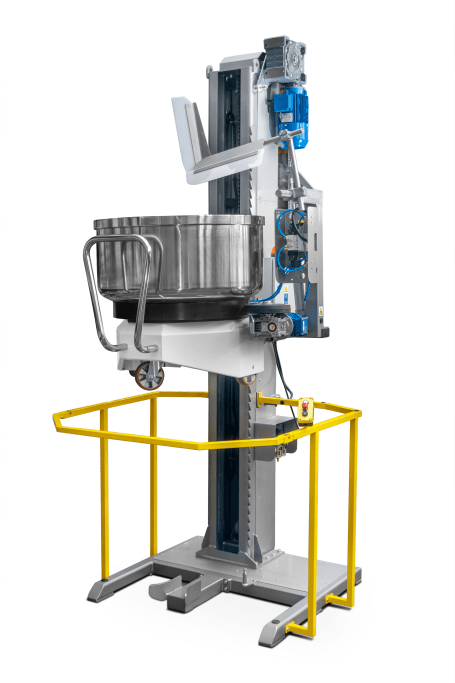

Bakery Mixer with Bowl Handling

Basically, dough mixers work especially well with modern dough lifters and bowl tippers. Furthermore, these systems lift and tilt bowls smoothly to any required height and direction. As a result, the dough can be transferred precisely to the next processing step. This also includes dividers, fermentation containers, or feed hoppers. Therefore, there is no need to move or rearrange production equipment. Therefore, the tipping system is usually hydraulic or electric. Moreover, it allows clean, controlled, and complete emptying of bowls. Additionally, in some setups, sensors monitor tipping speed and position in real time. In addition, stainless steel construction ensures hygiene and easy cleaning. Also, Some designs allow tipping to both sides or forward, depending on the layout.

Better Ergonomics and Safer Production Flow

Firstly, by using a bakery lifter, employees no longer lift heavy dough manually. That’s why, as a result, workplace injuries are reduced significantly. Furthermore, the transfer process becomes faster, safer, and more consistent. Moreover, in many bakeries, this setup increases daily production output with less strain on staff. Because bowl tippers are tailored to fit different bowl sizes and heights. That’s why, they can also match existing production lines with minimal adjustments. Furthermore, in most cases, setup time is short, and also maintenance needs are low. Therefore, combining a bakery mixer with a dough lifter and bowl tippers is the first step toward automation. Basically, it brings better efficiency, cleaner workflows, and modern standards to your dough production line.

GOT QUESTIONS?

SUPPORT AND CONSULTING

If you need assistance in choosing the right equipment,

call +48 (32) 661-42-00 or write to masz@masz.gliwice.pl