How to Automate Bread Production with Modern Machines?

Modern bakeries face growing challenges: increasing labour costs, the need for consistent product quality, and the demand for higher efficiency. Therefore, automation addresses these challenges by optimizing every stage of bread production. Starting from mixing ingredients to packaging finished goods. So, this article explains how to automate bread baking and highlights machines worth implementing, especially spiral mixers and bowl tippers.

Spiral Mixers – The Foundation of Quality Dough

Production of the bread starts with properly mixed dough. The spiral mixer blends flour, water, yeast, and other ingredients into a uniform, elastic mass. Moreover, its spiral arm and rotating bowl ensure consistent, intensive kneading. Spiral mixers come with fixed or removable bowls. Furthermore, for bakeries processing high dough volumes, removable bowl spiral mixers allow for efficient transport to the next bread production stage. Also, these machines often include programmable settings for kneading time and speed, improving consistency and reducing human error.

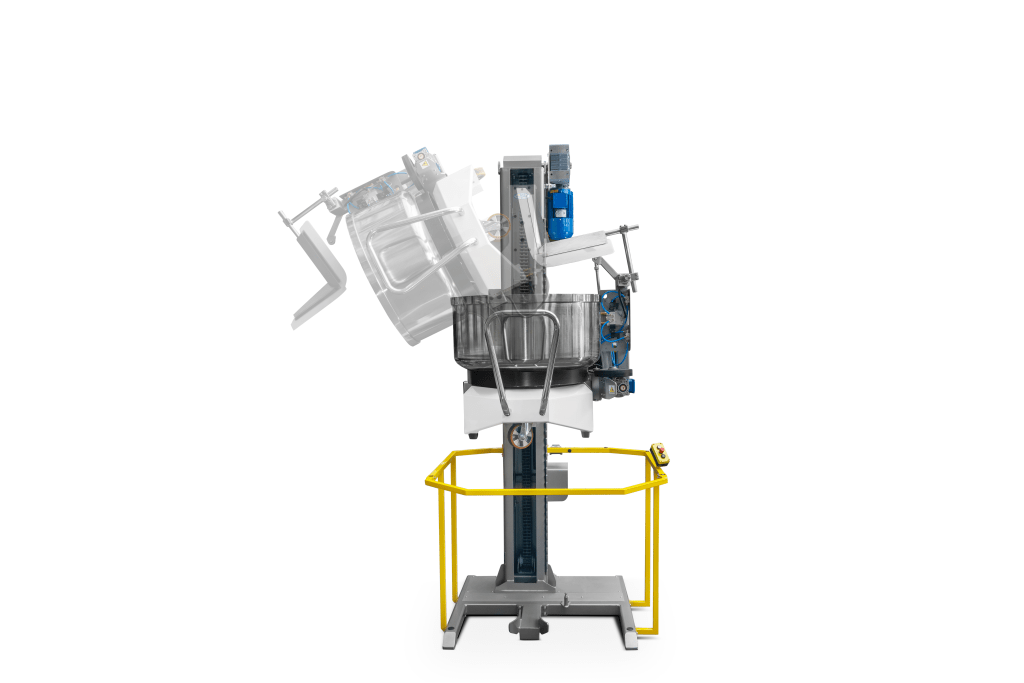

Bowl Tippers – Safe and Efficient Dough Handling

After mixing, dough moves to the next stage in bread production: dividing. Handling large dough quantities manually takes time and poses risks. That’s why many bakeries now use bowl tippers to automate this step.

Bowl tippers lift and tilt bowls to empty contents precisely into dividers or hoppers. Because they work efficiently and safely, reducing injuries and ingredient waste. Furthermore, this equipment improves workflow and increases bread production line efficiency, enabling continuous operation.

Dough Dividers – Precision and Consistency

The dough goes into dividers that portion it into consistent weights. Because this consistency ensures uniform baked products and supports efficient automated production of bread.

Bread Production – Even Shape and Proper Aeration

Next, dough pieces pass through conical rounders that rotate them along a cone. Also, this gives the dough a round shape and improves its structure — essential for high-quality baked goods.

Intermediate Moulders – Controlled Fermentation

Fermentation impacts flavour, volume, and crumb structure. Intermediate moulders allow resting between shaping stages, while moulders prepare dough for its final form. Furthermore, these machines stabilize fermentation and help maintain optimal conditions.

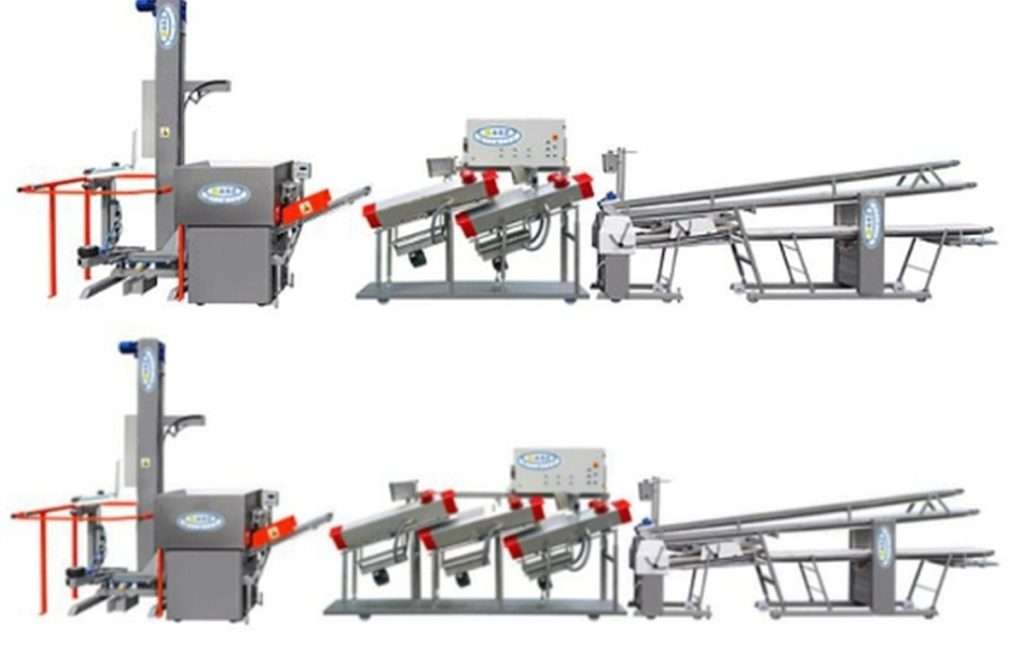

Moulders – Uniform Shape and Higher Throughput

Once proofed, the dough enters moulders that shape it into loaves, baguettes, buns, and more. Therefore, these machines maintain uniformity and are vital for high standard bakery production.

Bread Production and Baking Lines – The Final Stage of Automation

Fully automatic baking lines use rotary or convection ovens to bake bread without interruption. So, dough travels on belts through precisely controlled baking cycles. Integrated sensors and systems optimize every step, ensuring perfect results. Automating bread baking supports craftsmanship rather than replacing it. Spiral mixers, tippers, dividers, dough rounders, moulders, and rotary ovens form a complete bread baking line. So, this setup increases output, lowers costs, and improves consistency. In the summary, automation saves time and labour while giving bakeries a competitive edge in today’s fast-paced bread production industry.