Which Bread Slicer Should You Choose for Your Bakery? A Guide for Bakery Owners and Managers

When running a bakery, one of the key aspects is ensuring high quality and efficiency in the baking process. A proper bread slicer is a tool that not only simplifies daily work but also impacts the quality of products offered to customers. Choosing the right bakery bread slicer might seem complex, but with a few tips, you’ll be able to make the best decision.

1. Type of Slicer: Manual or Automatic?

The first step in choosing a slicer is deciding whether you prefer a manual or automatic model. Here’s a quick comparison of both options:

Semi-automatic slicer – A simpler device that requires some physical effort from the operator to slice loaves. Usually less expensive and easier to maintain. Ideal for bakeries with lower production volumes.

Automatic slicer – A more advanced machine that allows fast and precise slicing with minimal effort. Automatic slicers can operate continuously, making them perfect for busy, high-output bakeries. Generally more expensive but offer higher efficiency.

2. Slicing Type: Thick or Thin Slices?

Your choice also depends on the types of products you’ll be slicing. While bread is most common, bakeries also slice rolls and baguettes. Some slicers offer adjustable thickness, providing flexibility in production.

For bread – Most bakers prefer slicers with adjustable thickness. Depending on the bread type (e.g., white, rye, spelt), you might want thicker or thinner slices. If your bakery offers a wide range of baked goods, it’s worth investing in a slicer with this feature.

Slicer for baguettes and rolls – For delicate items like baguettes and rolls, the slicer must offer gentle and accurate cuts to maintain structure. Look for models that can handle varying bread textures.

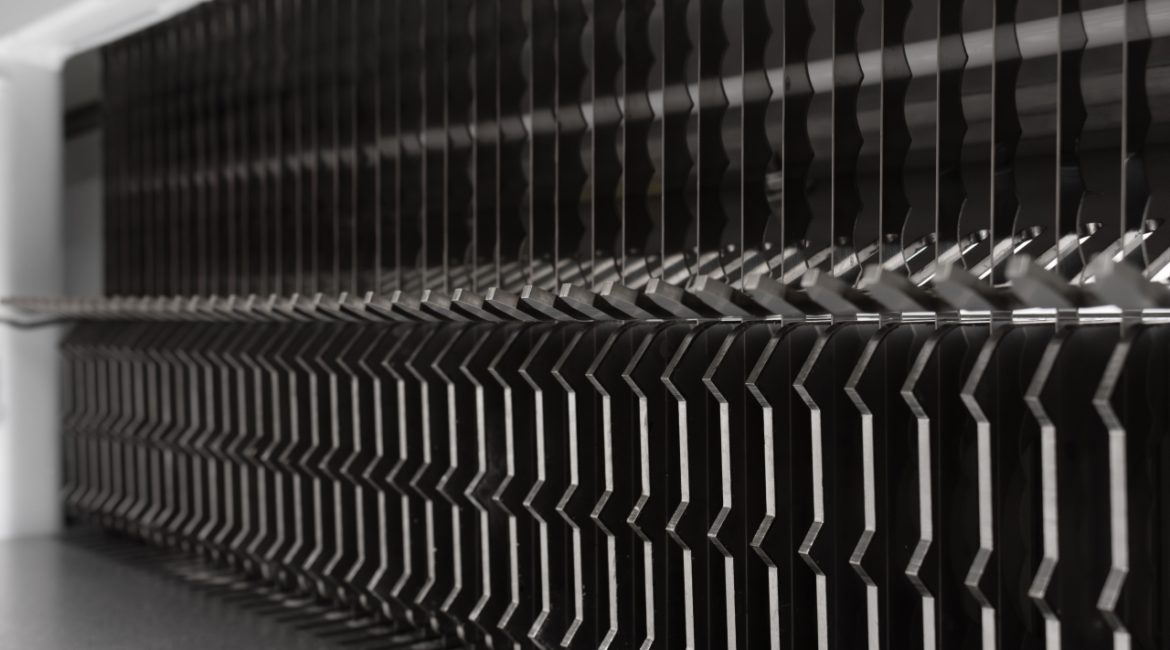

3. Material – Durability and Easy Cleaning

Bakery bread slicers are often made with powder-coated steel bodies, which are durable and easy to clean. When choosing a slicer, make sure its components can be disassembled and cleaned easily — hygiene is essential in bakeries.

4. User Safety

Bread slicers should include safety features to prevent accidental injury. Key features to look for:

- Blade guards – Prevent accidental contact with blades.

- Emergency stop button – Allows the machine to stop immediately in case of emergency.

- Non-slip feet – Ensure the slicer stays stable during use.

Also consider ergonomics—user-friendly machines reduce operator error and fatigue.

5. Performance and Capacity

The output capacity of your slicer is critical. Before choosing, evaluate how much bread you produce and how many loaves you need to slice daily. Slicers vary in performance, affecting productivity and cut quality—especially in large bakeries.

Small Bakeries (up to 360 loaves/hour)

For small bakeries producing limited quantities, compact slicers with outputs up to 360 loaves per hour are sufficient. These are typically simpler, more affordable, and easier to operate. Features include:

- Lower slicing speed – Sufficient for moderate output with consistent cuts.

- Manual or semi-automatic models – Ideal for small-scale daily operations.

- Compact size – Fits easily into tight bakery spaces.

Medium-Sized Bakeries (up to 470 loaves/hour)

Medium bakeries producing 400–470 loaves per hour require slicers that combine performance and precision. Features include:

- Moderate slicing speed – Allows fast and precise slicing.

- Automatic models – Enable continuous operation, ideal for growing output.

- Greater thickness adjustment – Suitable for various bread textures.

- Larger capacity – Can handle bigger or more loaves in one cycle.

These models also offer greater convenience, reliability, and are built for higher workloads.

Large Bakeries (2,000+ loaves/hour)

In high-volume bakeries producing up to 3,000 loaves per hour, top performance and machine durability are essential. Slicers for such bakeries should offer:

- Very fast slicing speed – Automatic slicers capable of 2,000–2,500 loaves/hour without compromising quality.

- Heavy-duty design – Built to withstand long operating hours.

- Advanced automation – Features like blade cooling or automatic loading ensure continuous, efficient workflow.

- Capacity for large loaves – Important for bakeries making big, traditional loaves.

In large operations, an automatic slicer with a packaging station is a must-have to maintain production speed and minimize downtime.

6. Price and After-Sales Service

Budget is also an important factor. Bakery slicers vary in price depending on brand, features, material, and capacity. Automatic models cost more, but if you run a large-scale operation, they’re a smart long-term investment.

Check what kind of support the manufacturer offers. Quality slicers are built to last, but in case of malfunction, fast and reliable service is crucial.

By investing in the right slicer, you’ll improve slicing accuracy, reduce labor, and enhance overall workflow—resulting in better product presentation and customer satisfaction.

Choose based on your production needs, and your bakery will run more smoothly, quickly, and efficiently.